Calculate Aquarium Thickness - How THICK must the Plexiglas be?

AQUARIUM THICKNESS CALCULATION

To determine the proper thickness for an aquarium made of ACRYLITE® GP acrylic sheet...

OK - this is for all you Einsteins out there - even if it's high school physics and math... please don't ask me the calculate this.. 🙂 - check out the Cyro Tech-Knowlogy site for a spreadsheet to help. You have to login in - but it is a killer info site.

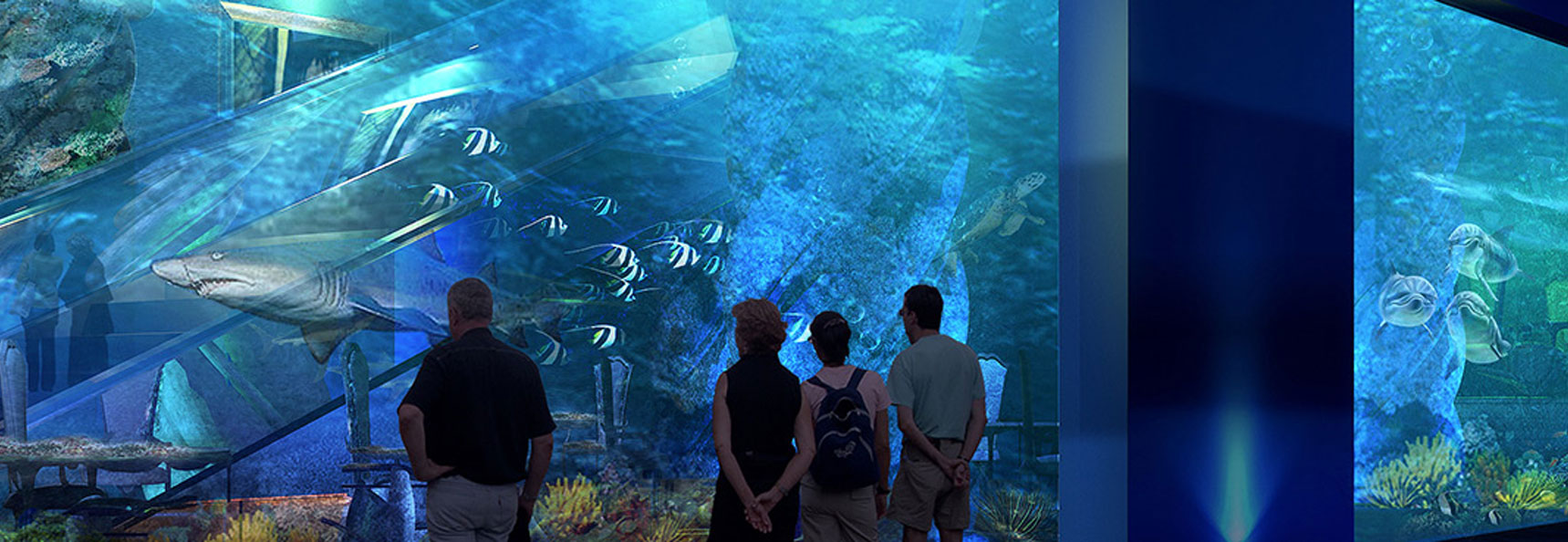

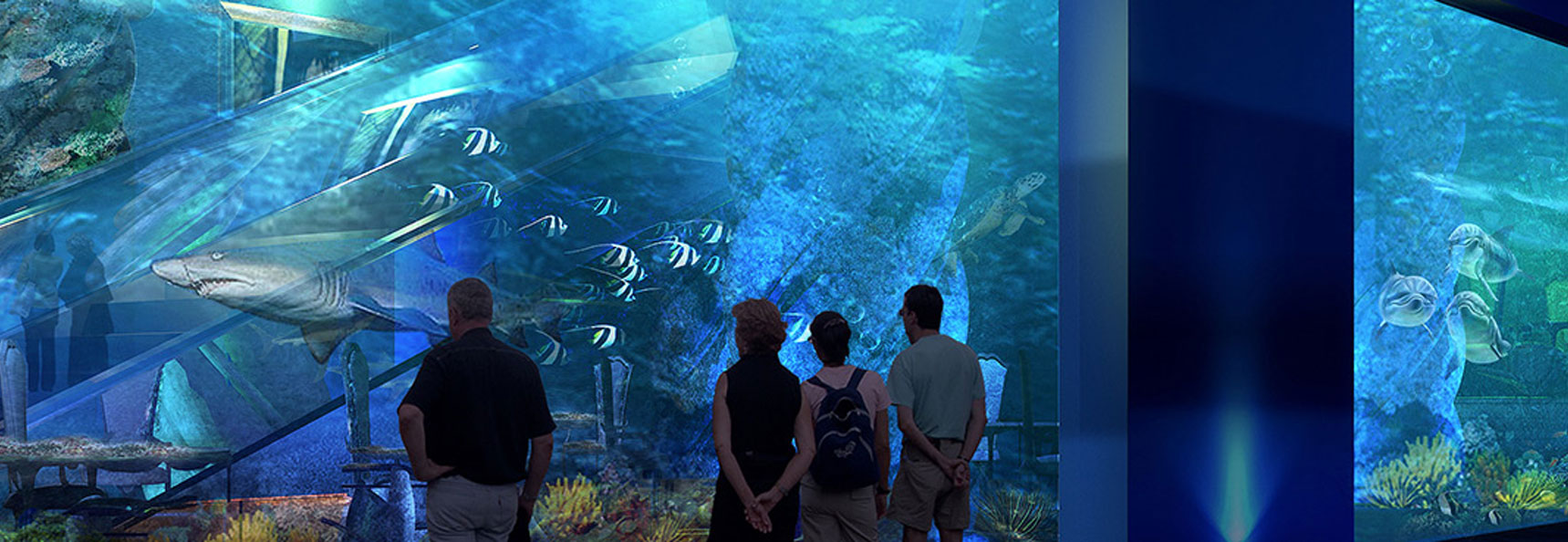

The aqaurium in the picture is 12ft long, 4ft high and about 3ft wide in the middle. It was constructed of 2" thick acrylic sheet, the outer walls were thermoformed into convex sheets, and please note the "top cap" made of 1" thick plexiglas sheet, then routed out for access holes. This top cap also creates a structural member that keeps the outer walls from bulging under pressure. This aquarium is now doing service in upstate Michigan.

CYRO recommends that all acrylic water vessels, including aquariums, should be constructed with cell cast ACRYLITE GP sheet. This requirement exists for two reasons:

ACRYLITE GP sheetis more capable of withstanding continuous loads than continuously manufactured or extruded sheet.

ACRYLITE GP sheetmaintains a high level of mechanical strength after water absorption has reached equilibrium.

Cemented joints must withstand the effects of the continuous hydraulic pressure and the high level of water absorption for many years. Two-part polymerizable cements are recommended for this to meet this requirement. See Weld-On #40 information in the blog. Solvent cements are NOT recommended.

To determine what thickness acrylic sheet should be used, the calculation below can be used assuming the base is uniformly supported.

T - thickness of sheet

H - height of tank

L - length of tank

Required Thickness T (in)=

q = maximum water pressure (lbs/in.2) = (0.0361 lbs water/in3)* H (inches)

H = aquarium height (inches)

α = maximum permissible stress for ACRYLITE GP in an aquarium (750 psi)

β = coefficient from L/H relationship as follows:

L/H

0.25

0.50

0.75

1.00

1.50

2.00

3.00

4.00

β

0.037

0.120

0.212

0.321

0.523

0.677

0.866

0.940

Note: For L/H ratios not shown, use the β value for the next higher ratio.

Example:

L = 36 in.

H = 15 in.

L/H = 2.4 therefore: b = 0.866 (taken from the chart for L/H = 3.0)

q = (0.0361 lbs/in3) x (15 in) = 0.542 lbs/in2

T (in) =

= 0.375 inches

If a top is cemented on (this would have 2 cutouts to prevent bowing), the recommended thickness in 0.375 inches. With an open top use a safety factor of 1.5, bringing the recommended thickness to 0.563 inches to be used in this size tank. Since a thickness of 0.563 is not made, simply increase this to 0.740" (3/4") which is stock.

OK - did I blow your mind? WWPGD? If you want to build an aquarium, and the edges are hidden by framework, or the mounting in a wall, etc. then use 1/2" CAST ACRYLIC SHEET for aquariums that are 15" high x 20" wide x 36" long. Make sure there is a top cap to keep sides from bulging. 24" x 24" x 48" - use 3/4" sheet and 30"x30"x48" use 1" sheet. Always use a top cap sheet to hold side together!

If you are not skilled with gluing Plexiglas, search out a local plexiglass fabricator in your area. Typically under the Yellow Page heading of Plastics - Fabricators. If the edges are showing, make sure the fabricator defines how bubble-free their bonds will be and the quality of the edge polishing. Expect to place a 50% deposit on the order and the balance when complete to your satisfaction. To save money, identify what edges do NOT need to be polished - that saves time and your money!

http://diyfishkeepers.com/AcrylicThicknessCalculator.htm

http://www.cnfish.cn/jsq.aspx

Glazing thickness is affected by:

Construction of the tank;

Dimensions of the tank;

Height of the water column;

Presence of ribbed stiffeners (if there are no stiffening ribs, the thickness of glazing should be greater, otherwise acrylic tank will be exposed to a heavier pressure on walls and bottom surface);

Climatic region;

Material fatigue;

Availability to people (for pools);

Earthquake activity.

psi Pounds per square inch

PG, your acrylic purchasing expert

https://www.pgacrylic.com/