Shanghai PG Aquariums & Landscaping Co., Ltd China

Add: No.165, Tianshan Rd, Shanghai, China | Ph: (86) 21 5279 8309 | Email:

[email protected]

Acrylic Care---Do’s & Don’ts

Do use only mild soap or detergent and lukewarm water to clean the surface of acrylic panel.

Do use only clean soft cotton cloth or microfiber cloth, applying only light pressure. Rinse with clean water and dry by blotting with a damp cloth or chamois. Grease, oil or tar may be removed with a good grade of hexane, aliphatic naphtha, or kerosene.

Notes for Acrylic Panel Installing Timing and Care

Installing Timing

According to acrylic thicker panel character of expansion and contraction with different temperature, the best installing timing for acrylic panel is 2 months before official use.

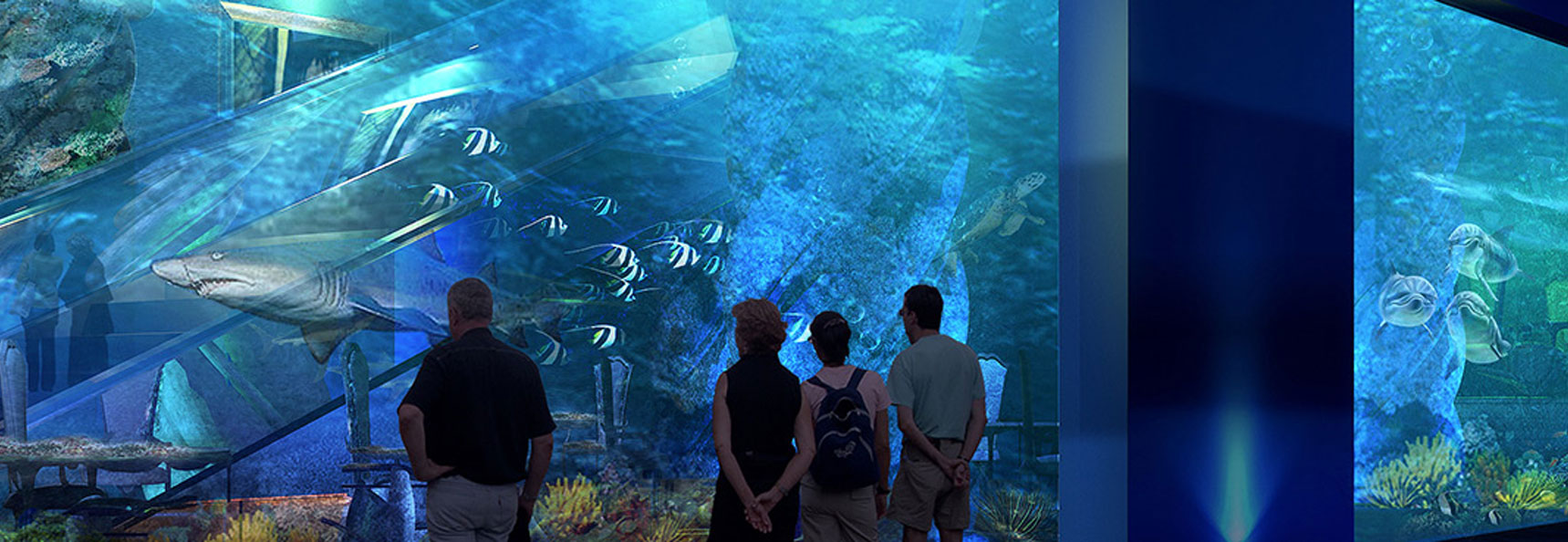

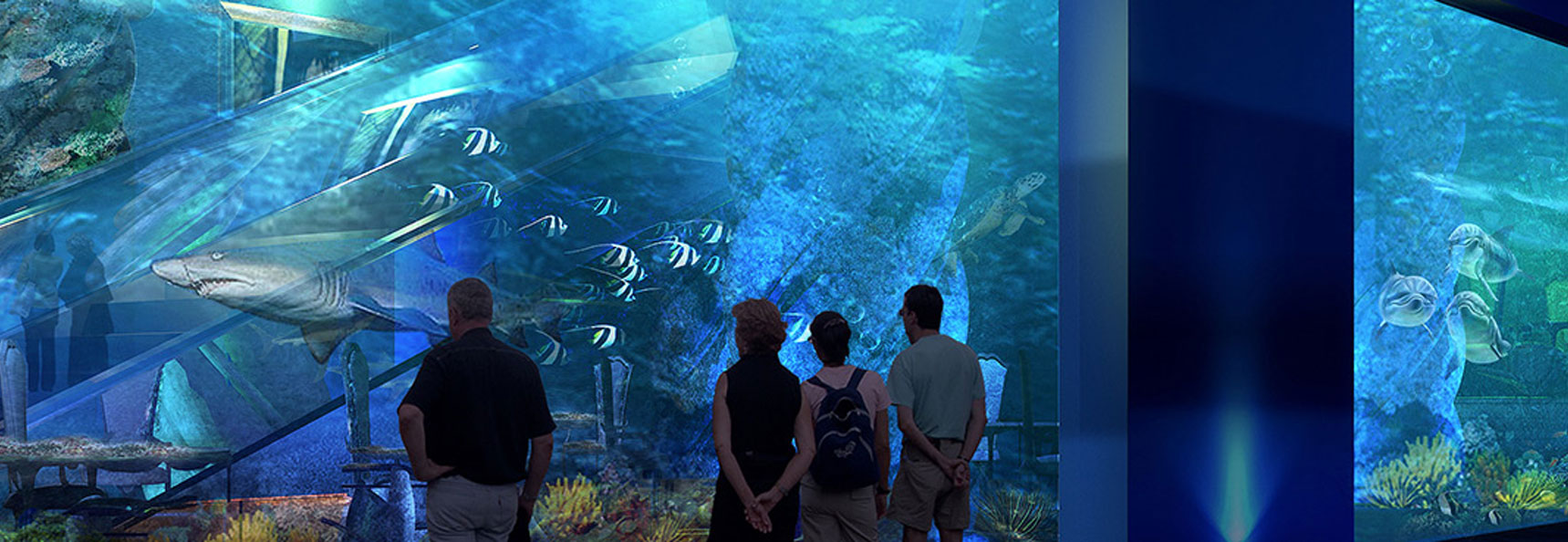

Large aquarium acrylic aquarium market is heating up rapidly

The consumption market of large fish tanks is surging, and more and more hotel villas, supermarkets and playgrounds are optimistic about this new market, because large fish tanks have occupied an increasingly important position in the consumer market. Everyone knows that intimate contact with nature has become the pursuit of modern urbanites, and the refined aquarium landscape can make people and nature more close

The acrylic density is almost half of the glass

Plexiglass, which is a common name, also has a trade name called "Acrylic", whether it is the name of the product "acrylic" or the popular name "plexiglass", which is actually not accurate. This material looks very beautiful, its official name is: polymethyl methacrylate. This is a thermoplastic that has been invented very early and has a long history.

What are the acrylic panel processing technologies

Unloading: Cutting the acrylic sheet with a cutting machine. This requires the size of the acrylic product to be accurately opened to avoid material waste.

The bonding of acrylic sheets

Acrylic sheet bonding is a very important part of acrylic processing. How to show the clear and transparent characteristics of acrylic, embody the value of acrylic crafts, maximize the grade and quality of acrylic crafts, bonding technology starts here It has played an important role.

Common bonding skills of acrylic

Acrylic shadowless adhesive, which participates in the curing reaction by dissolving the acrylic and releasing the curing agent to achieve the bonding between the acrylics. From the physical and chemical point of view, it has the commonality of the above two adhesives; from the viewpoint of operability and bonding effect, it completely overcomes their disadvantages and has their advantages. And the adhesive itself is in full

Precautions for the bonding of the acrylic sheet

Bevel bonding: The bonding bevel must be at a 90 degree angle to prevent displacement of the surface to be bonded. It should be uniform and slow when applying Kerrybond. The master can be removed after it has been fully cured.